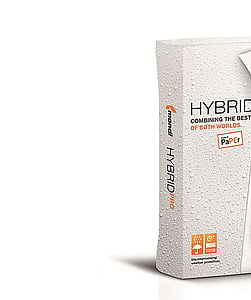

HYBRID PRO

The HYBRIDPRO bag is Mondi’s hybrid solution, offering the advantages of a plastic bag, yet is fillable on conventional paper bag filling systems. Outdoor storage for lengthy periods of time due to a film barrier against direct rain, moisture ingress and dust.